Home Design

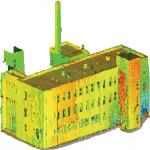

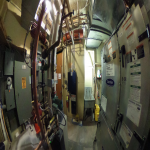

As 3D laser scanning has improved in speed and quality, the return on investment to laser scan Manufacturing and Industrial Plants has become so high that it is now almost standard practice to start new projects with scanning. Scanning combined with three-dimensional digital twin modeling is a powerful tool for reducing both construction and operational costs.Large Scope AreasWith modern laser scanning equipment, anyone can scan small areas with just a few hours of training. Scanning large areas is a very different story. Manufacturing and Industrial Plants are often measured in hundreds of thousands if not millions of square feet, and they require a very different approach to scanning. Attempting mega-project scanning without specialized knowledge will yield very poor results and failed projects.Schedules can be a challengeWith many plants running 24 hours per day, finding times to scan can be a challenge. Areas requiring lock-outs, for example, can only be scanned during downtimes. Developing a schedule that gets the job done is often complex and requires some creative solutions.Safety must be a priorityManufacturing and Industrial Plants are no place for the inexperienced. Anyone doing work in plants should have a fully documented Safety Policy and training program focused on the industrial space.Rapid ChangeWith the steady progress towards Industry 4.0, the rate of change in manufacturing and industrial plants can prove a significant challenge. HDT has innovative solutions for data management that make scanning feasible in even the fastest-changing environments.